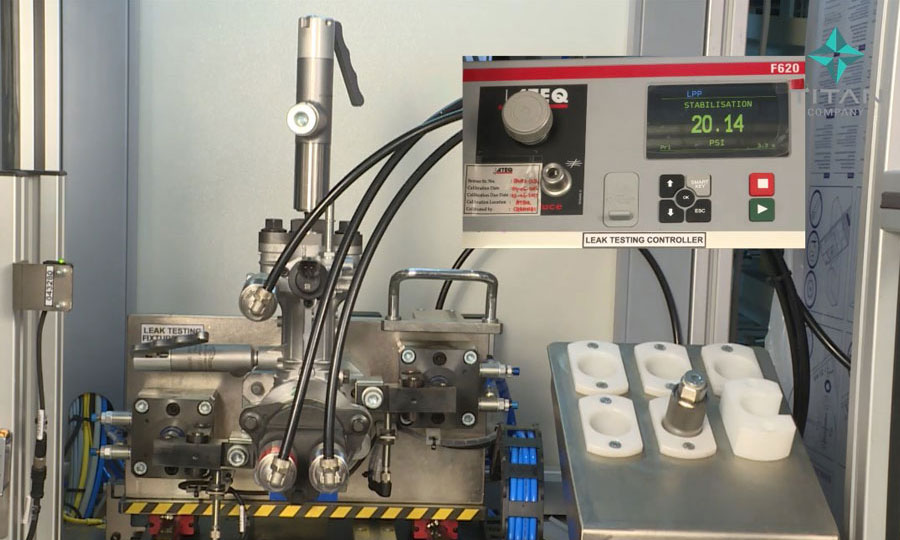

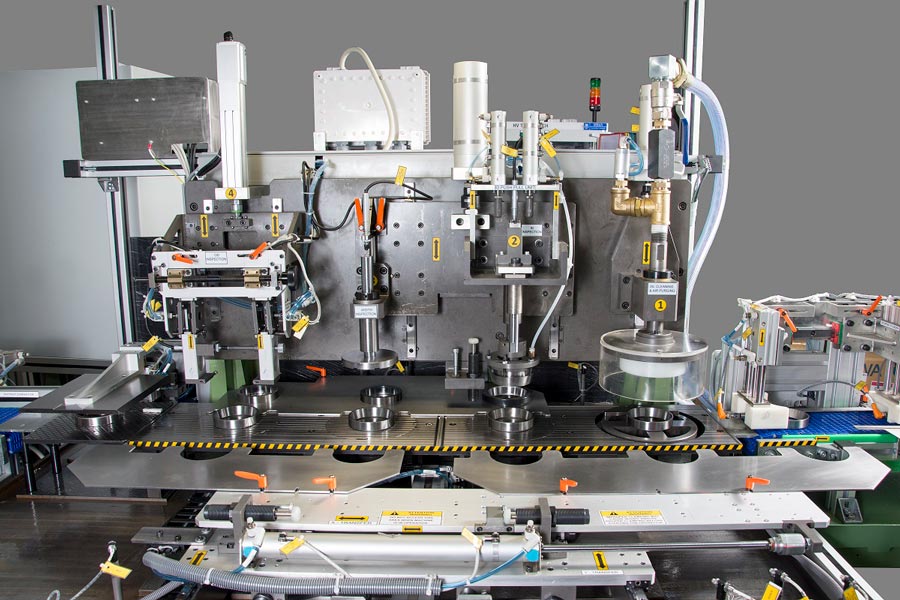

Leak Testing

Leak testing plays a vital role in assembly and manufacturing process. It ensures the quality and reliability of the product there by avoiding field failures (non-destructive method). A leak is a flow of gas /liquid into or from a controlled volume in a product exceeding its allowable limits. Leak also requires a pressure difference to generate the flow.

This leak testing also requires thorough understanding of product material, volume of the product, allowable Leak Rate, Seal/Ports Geometry, Surface Finish, etc.

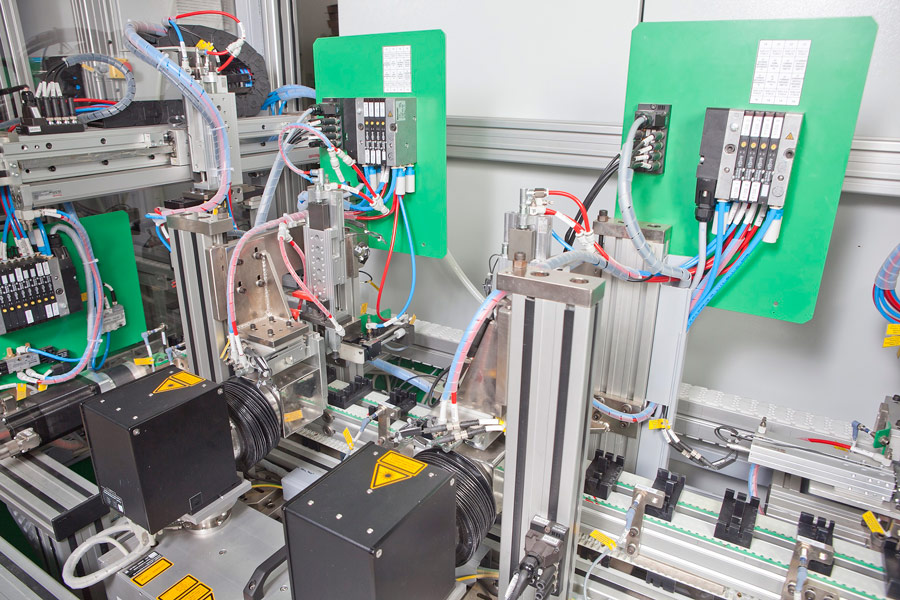

Reliable Leak Testing demands the selection of right electromechanical system elements thereby ensuring system accuracy. As a part of the complete turnkey solution, we provide customer, the required solution for the product for Accurate Leak Detection. The different methods include:

- Water Leak Testing

- Air Leak Testing - Differential pressure, Differential pressure decay

This leak testing also requires thorough understanding of product material, volume of the product, allowable Leak Rate, Seal/Ports Geometry, Surface Finish, etc.

Reliable Leak Testing demands the selection of right electromechanical system elements thereby ensuring system accuracy. As a part of the complete turnkey solution, we provide customer, the required solution for the product for Accurate Leak Detection. The different methods include:

- Water Leak Testing

- Air Leak Testing - Differential pressure, Differential pressure decay