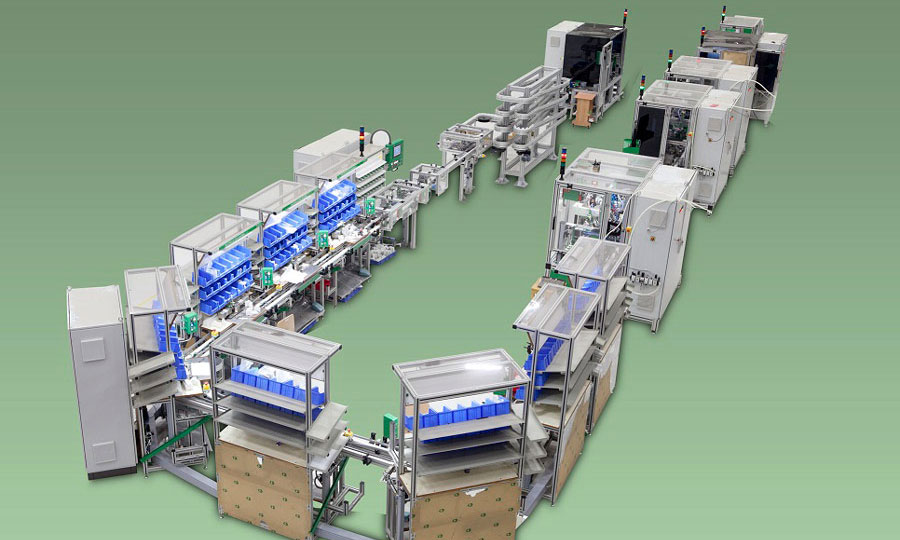

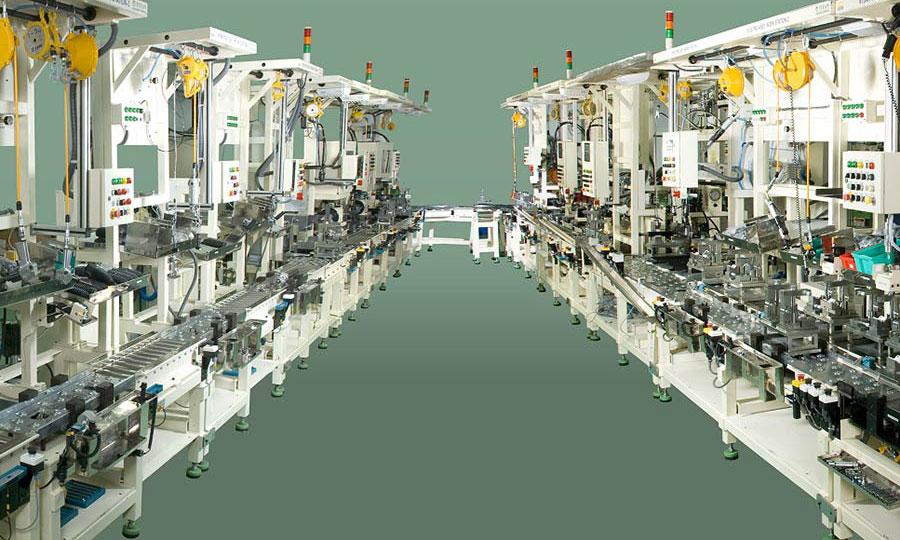

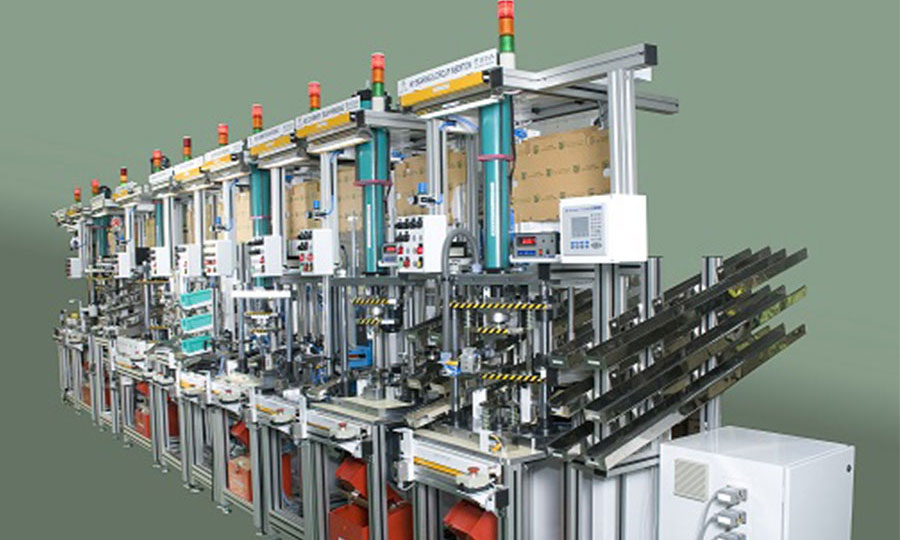

Lean Assembly Cells

Lean assembly concepts developed by TEAL aids in maximizing the overall efficiency of the solution. Reduction in WIP with single piece flow which leads to reduction in customer’s time to market

Assembly lines are conceptualized and designed eliminating all the MUDA or waste in the process. Few areas of waste eliminations considered in our solutions are:

- Transportation Losses- eliminating non value added movement of components

- Work in Progress & Waiting- optimization with implementation of single piece flow and eliminating interruptions

- Motion Losses when excess movement of people and systems leads to wastage. Eliminated by effective motion study analysis and innovative design concepts

- Over Processing is eliminated by innovative design methodologies to arrive at best process for any operation

- Defects elimination by robust DFMEA at design phase and incorporating poka yoke systems

Lean assembly concepts developed by TEAL aids in maximizing the overall efficiency of the solution. Reduction in WIP with single piece flow which leads to reduction in customer’s time to market

Assembly lines are conceptualized and designed eliminating all the MUDA or waste in the process. Few areas of waste eliminations considered in our solutions are:

- Transportation Losses- eliminating non value added movement of components

- Work in Progress & Waiting- optimization with implementation of single piece flow and eliminating interruptions

- Motion Losses when excess movement of people and systems leads to wastage. Eliminated by effective motion study analysis and innovative design concepts

- Over Processing is eliminated by innovative design methodologies to arrive at best process for any operation

- Defects elimination by robust DFMEA at design phase and incorporating poka yoke systems