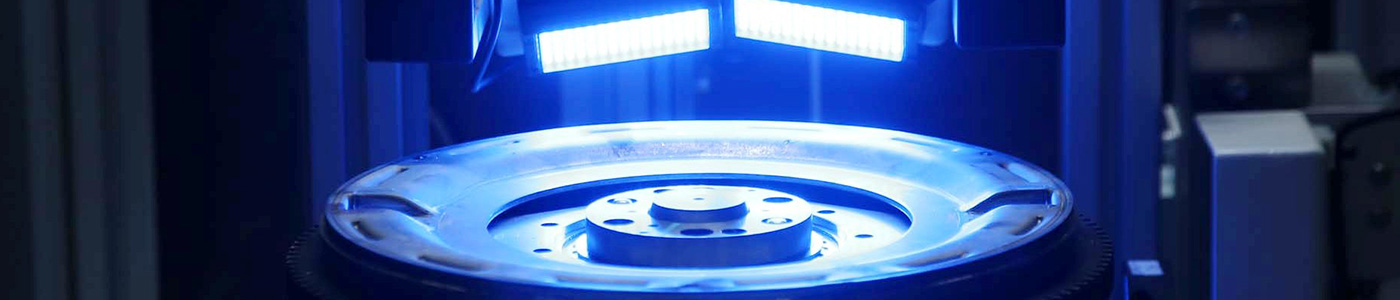

Testing & Measurement

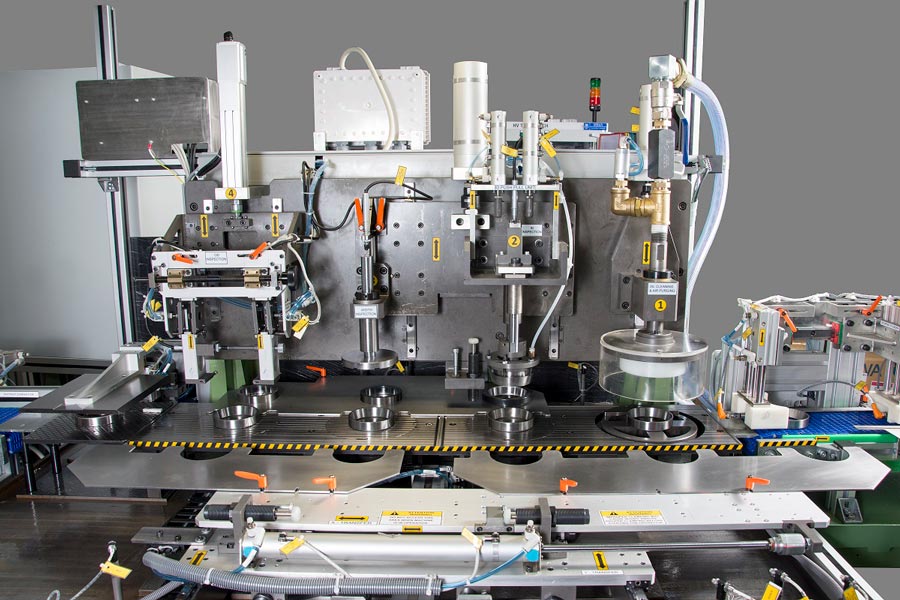

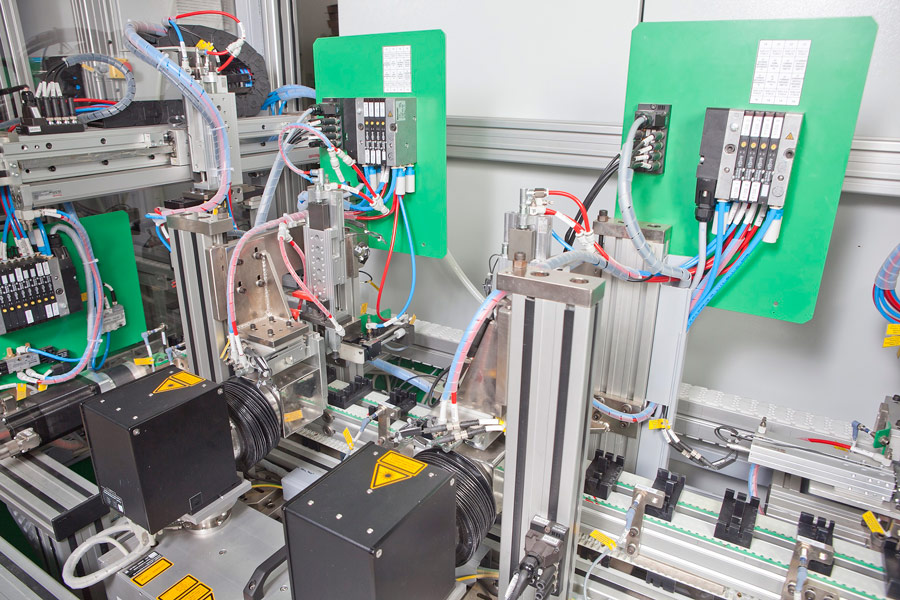

As technology get embedded into the production processes of all industries,the role of inline as well as end of line inspection and testing gains precedence. Closed loop systems which bring about intelligent and self learning machines define the present and the future of successful manufacturing.

With our specialization in building automated test systems for all manufacturing sectors, we offer customized solutions for your testing requirements.