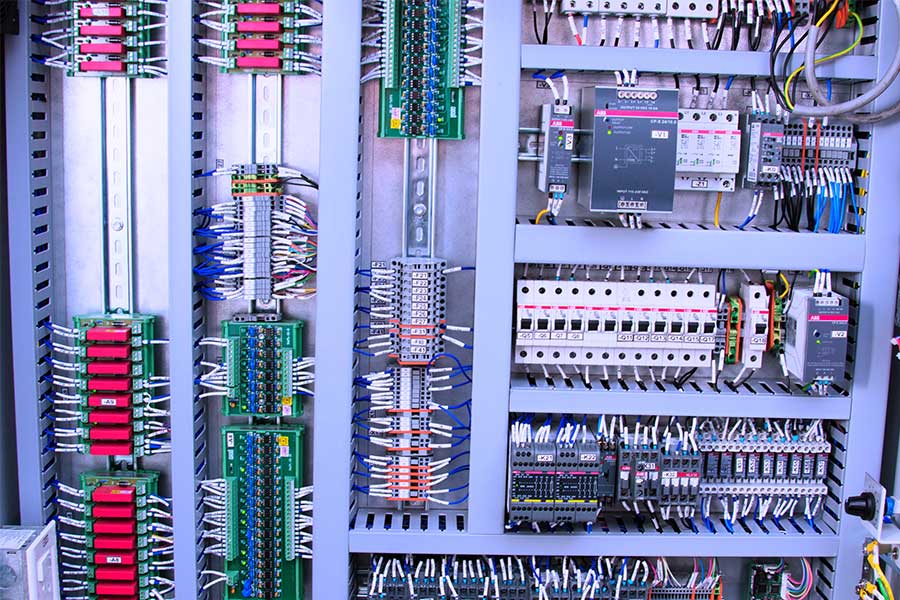

PC/NI System

As part of the complete turnkey solution, we provide PC/HMI based control system with SCADA as part of our machine for monitoring and controlling the sequence of operation as well as to monitor the process efficiently. The PC/HMI along with real-time data acquisition hardware (a PCI based modular system) shall control, capture data and do analysis based on application requirements. PC/HMI system ensures high speed communication with the machine through Ethernet/IP, Profinet, Profibus etc.

In assembly line, the SCADA based system is developed for ‘product traceability using RFID and database’. Also, the machine parameters can be configured using Modules. Additionally, SCADA provides Monitoring, Report and Analysis for OEE, Production Data, Machine Status etc.

For testing applications where data logging is mandatory, we use Engineering Software, a graphical programming tool that can Access, Restrict, Configure and Control the machine operation. The software features High Speed Data Logging, Diagnostics, Password Protection, Real-time Trend Graph, Data Import/Export Options, etc .This user interface in the machine provides a Graphics-Based Visualization of the control system from which the operator can able to access the systems menu, settings screen, Diagnostics screen, Production screen, etc

In assembly line, the SCADA based system is developed for ‘product traceability using RFID and database’. Also, the machine parameters can be configured using Modules. Additionally, SCADA provides Monitoring, Report and Analysis for OEE, Production Data, Machine Status etc.

For testing applications where data logging is mandatory, we use Engineering Software, a graphical programming tool that can Access, Restrict, Configure and Control the machine operation. The software features High Speed Data Logging, Diagnostics, Password Protection, Real-time Trend Graph, Data Import/Export Options, etc .This user interface in the machine provides a Graphics-Based Visualization of the control system from which the operator can able to access the systems menu, settings screen, Diagnostics screen, Production screen, etc